Precision Plastic Mold designed by UG NX11.0 and AutoCad

1 cavity mold for auto part with PP66-50%GF Black material.

| Manufacturing | Injection molded parts |

| Material | Mold:718H, NAK80, S136H,

DIN1.2344,LKM2083,LKM2344,8406,8407,S136,LKM2767 etc. Product:PP,PC,PS,PE,PU,PVC,ABS,PMMA,PEI ect |

| Design Software | UG,PROE,CAD,Solidworks,etc |

| Cavity Variety | One-stop solution,Multi-cavity mold,Family plastic mold,Hot runner

plastic mold |

| Quality Control | ISO/TS16949:2002 and ISO14001:2004 system |

| Business Scope | Mold and parts designing and making,Parts machining,Injection

molding, CNC prototype manufacturing |

| Mold Processing | CNC EDM machine processing then assembly and trial |

| General Size | According to your 3D drawings |

| Manufacturing Machines | CNC,EDM,MILLING,WIRE EDM,etc |

| Runner | Hot Runner/Cold Runner |

| Running | Hot Runner/Cold Runner |

| Plastic Mould life | 300,000-3,000,000 shots |

| Ejection System | Ejector pin or ejecting block |

| Mold Standard | Domestic standard,HASCO standard,DME Standard,MasterFlow Standard |

| Mold Making Time | 15-35 days |

| Mold Life Time | 500000-1000000pieces |

| Plastic Material | ABS,PP, PC, PS, PE, PET, POM, PA,PU, PVC, PEI,HIPS, PMMA etc. |

Issue Solution example

Weld Lines

Description: Weld lines are actually more like a plane than a line that

appears in a part where molten plastics meet each other as they

flow from two different parts of the mold.

Causes: Weld lines are caused by the inadequate bonding of two or more

flow fronts when there is partial solidification of the molten

plastic.

Remedies:

- Raise the temperature of the mold or molten plastic.

- Increase the injection speed.

- Adjust the design for the flow pattern to be a single source flow.

- Switch to a less viscous plastic or one with a lower melting

temperature

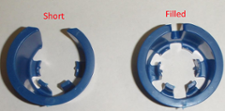

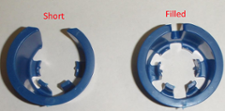

Short Shot

Description: As the term implies, short shots can be described as a situation

where a molding shot falls short. This means that the molten

plastic for some reason does not fully occupy the mold cavity or

cavities, resulting in a portion where there is no plastic. The

finished product becomes deficient because it is incomplete.

Causes: Short shots can be caused by a number of things. Incorrect

calibration of the shot or plasticizing capacities can result in

the plastic material being inadequate to fill the cavities. If the

plastic is too viscous, it may solidify before fully occupying all

the cavities and result in a short shot. Inadequate degassing or

gas venting techniques can also result in short shots because air

is trapped and has no way to escape; plastic material cannot occupy

the space that air or gas is already occupying.

Remedies:

- Select a less viscous plastic with higher flowability. This plastic

will fill the hardest-to-reach cavities.

- Increase mold or melt temperature so as to increase flowability.

- Account for gas generation by designing the mold so that gas is not

trapped within the mold and is properly vented.

- Increase the material feed in the molding machine or switch to a

machine that has a higher material feed in the event that the

maximum material feed has been reached.

FAQ:

1.Why choose GOM?

High Quality and short lead time with best engineering service to

bulid long-term business relationship with customer.

2.What GOM service?

-Components manufacturing

-Plastic molds building

-Injection producing

-Painting & Plating

-Assemble

-Engineering support

3.How to control the quality?

Every process finish must make the measurement by CMM and should be

passed then can do the next process.

4.How to provide after-serivice on the overseas?

We have 3 Parters in different area can deal it, in Mexico,Czech

and Spain.

=======================================================================================

Our Main Services:

1. Plastic molds:

Hot runner mold, precision mold, over mold, two-shot mold,

unscrewing mold, multi-cavity mold, IML/IMI mold, Stack mold,

Die-casting mold, etc.

90% molds exported to North America, South American, Europe and

Australia.

2. Injection Molding:

We have rich experience in molding various engineering grade

resins:

ABS, PC, PC+GF, PC/ABS, PBT, PA6+GF, PA66+GF, PPS, PU, PP, PE, TPE,

TPU, LCP, Ultem, etc.

3. One Stop Services

Based on our strong engineering capability,GOM provide a full turnkey solution for customers bespoke plastic

injection moulding needs inclusive of design, development, mould

tooling, production and post moulding support.

• 3D Scanning

• Prototype

• Painting

• Pad-printing

• Silk-Screen Printing

• Hot Stamping

• Plating

• Color Match

• Ultrasonic Welding

• Automation

• Production Line Assembly

• Precision Metal Parts

• Die casting Parts